Speak to our technical team about pail filling:

sales@paquip.com or call/text (813) 252-0206

Request a Quote for Additional Options:

- Stainless steel / Washdown - for food processing applications

- Diving nozzles - for foam control, reducing splashing, or controlling fuming

- Full automation - including powered conveyor, label applicator, lid placement, and lid press

- Additional nozzle types - such as for paints/coatings, food processing, or viscous fluids

- Additional conveyor options - tighter roller spacing, washdown, powered systems, custom heights/lengths, curved sections, and transfers

- High accuracy scales - Resolution down to 0.02lb and repeatability down to +/-0.05lb

- Container positioners - for jerrycans/carboys, bag-in-box, or smaller bottles, such as 1 gallon

- Nozzle & hose quick-change systems to limit contamination between production runs

- Corrosive products - all plastic wetted systems available

- Hazardous locations - Class I Division 1 or 2

- Nitrogen blanketing

- Splash guard

- Compressed air/nitrogen clearing - Assists removing residual fluid

- Additional pump options

- Additional power options (120v to 575v)

- CIP suitable systems

- Mobile casters

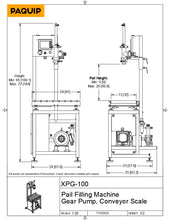

The XPG-100 is a semi-automatic pail and gallon filling machine designed with a powerful pump for viscous as well as easy-flowing product and fast filling. Options are available for filling containers as small as 1 liter or 1 quart. The XPG-100 is a single nozzle/pump version of the XPG-200.

Packages available specifically for your industry:

Coatings (paint, epoxy, urethane) Lubricants Agricultural Personal Care Food-processing Chemicals Cleaning Products Adhesives

Additional Information:

Standard equipment includes: Fixed nozzle, pump, scale, and powder coated frame. Diving nozzle, washdown, and hazardous location packages are available.

Pail filling capabilities, included standard:

- 23”x15” roller conveyor with load cells

-

Fast filling speeds:

- Gear pump: up to 15 seconds (per 5 gallon pail)

- Centrifugal pump: up to 9 seconds (per 5 gallon pail)

- Air-operated pump: up to 9 seconds (per 5 gallon pail)

- Fill all types of pails: open top, square carboys, etc

- Fill liter, quart, or gallon containers (requires additional options)

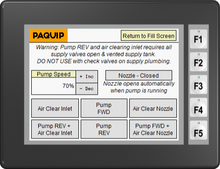

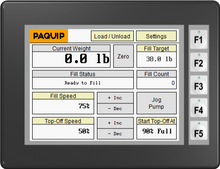

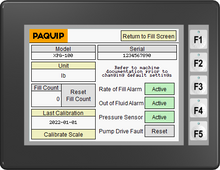

- 7” touch screen for weight readout, setting weight target, and motor speeds

- Save up to 255 fill profiles for different container sizes and products.

- Integrated quality checklist via the touch screen for switching between fill profiles and during system startup. (available option: barcode or RFID scanner integration for verifying supply tank, pump, or nozzle matches selected fill profile)

- Variable fill speed with auto slow top off feature

- Up to 1.5” hoses available to accommodate higher viscosity fluids

- Adjustable height no-drip nozzle

- Sanitary fitting connections for easy hose swaps

- Advanced computer controls with out-of-fluid detection, nozzle open detection, unexpected weight on scale, air-supply pressure monitoring, and more

Standard filling machine equipped with:

- High power pump, with optional materials and seals for fluid compatibility

- 7" Color touch screen

- Roller conveyor scale

- Powder coated welded steel frame (stainless steel washdown or epoxy coated corrosion resistant frame available)

- Sanitary/tri-clamp stainless steel wetted path with 1.5" supply hose barb connection. Pump wetted materials may vary.

- Fully adjustable nozzle position - Adjust the nozzles up and down to fit any pail type up to 18" high (additional height available upon request)

Filling Specifications:

| Fill Speed | Up to 6 CPM | |

| Measurement Method | Weight¹ | |

| Fill Accuracy |

+/- 0.1 lb (gear or lobe pump) +/- 0.2 lb (centrifugal pump) +/- 0.2 lb (AODD pump) (high-accuracy models available) |

|

| Viscosity Range |

1-10,000 cP (gear pump) 1-800 cP (centrifugal pump) 1-50,000 cP (AODD pump) 1-1,000,000 cP (rotary lobe pump) |

|

| Fluid Particulates |

|

|

| Fluid Temperature | Max: 120°F (49°C) Min: 32°F (0°C) (additional temp range available) |

|

| Fluid Supply Requirements |

Gear, lobe, & Air-operated pump: self-priming pump can draw fluids from ground-level (such as from an IBC tote) Centrifugal pump: requires elevated fluid source or a vacuum primer to initially fill pump housing. |

|

| Corrosive Fluids |

Yes, depending on pump type (Plastic/non-metallic options and chemical-resistant epoxy frame coating available for highly corrosive applications.) |

|

| Foamy Fluids | Yes, but diving nozzles are recommended | |

| Electrical Requirements |

208-240VAC 50/60hz, single phase, 19A for electric pump models 120VAC 50/60hz, 5A for air-operated pump models (Three phase and higher voltage available) |

|

| Air Requirements | 80 PSI @ 3 CFM |

* Fill speed may vary based on fluid & bottle characteristics

* Optional parts and upgrades may be required for compatibility with certain fluids

¹ With standard equipment, the net weight measurement is used as a proxy for determining filled volume and not for legal-for-trade weight measurements. Contact Paquip if your application requires NTEP-certified scale equipment.